Overhead Conveyor Parts Washers

TYPHOON®-OCW

Key benefits

- Compact design saves floor space

- Hanging parts provide excellent drainage

- Can be integrated with existing overhead conveyors

- Adjustable conveyor speed for variable process times

- Possibility of a multi-stage process by adding extra modules

- Low and easy maintenance

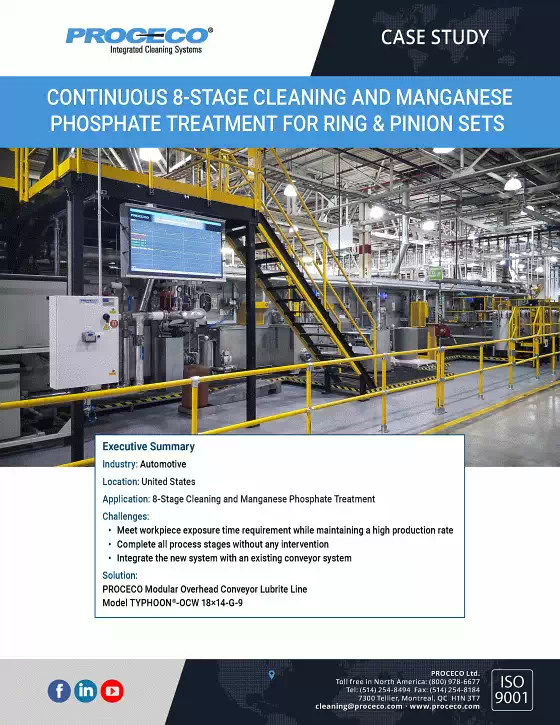

Overview

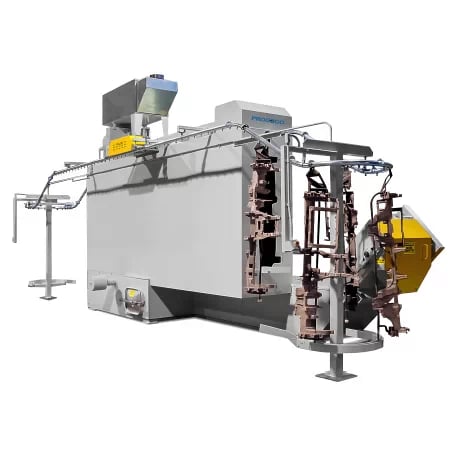

The TYPHOON®-OCW incorporates a powered monorail overhead conveyor to move parts through each process. The monorail parts washer design saves floor space by hanging long parts from the conveyor vertically rather than conveying them horizontally.

The PROCECO TYPHOON®-OCW monorail industrial parts washer can be engineered for parts cleaning, surface pre-treatment, and treatment processes such as phosphating and Lubrite®. Because of PROCECO's modular design approach, various standard modules can be added together to create a multi-stage process. Available modules include recirculated spray wash and rinse, immersion, ultrasonics, drying, and cooling.

To further customize a monorail industrial parts washer to meet your specific application needs, you can choose to incorporate several other options, such as automatic loading, custom designed part-holding fixtures, and cleaning solution filtration.

- Specification sheets

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

TESTIMONIALS

“... Proceco has demonstrated the supplier “partner” Ford is looking for in long term plans of the company...”

Robert L. Lorenz

“... where did you get your part washer? The name Proceco was the go-to company for part washing. I did research three vendors for our requirements. Proceco clearly was the leader in the procurement process...”

Todd Martin

“... Apres 8 ans de service aucun anomalie n'a ete enregistree sur la machine...”

M. Chagal

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.