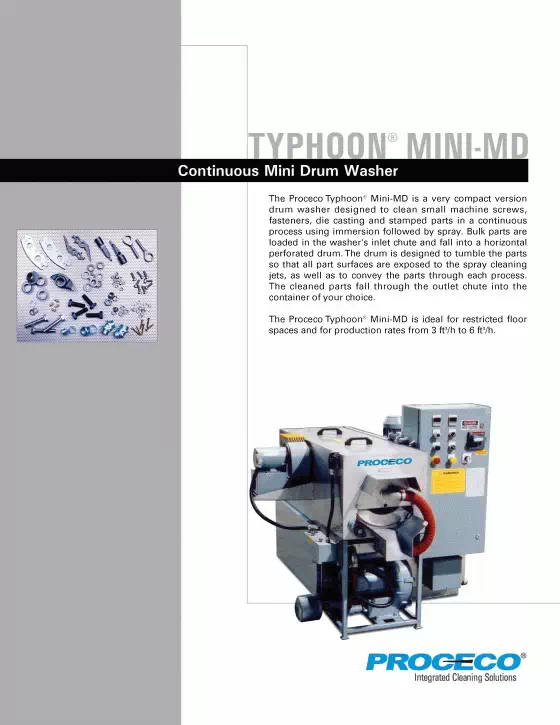

TYPHOON®-Mini-MD

The PROCECO TYPHOON®-Mini-MD is a smaller drum washer for customers seeking an economical wash & blow-off only solution for cleaning small parts such as machine screws, fasteners, die castings, and stamped components in a continuous process. Just as with the large MD, the Mini-MD is designed to tumble the parts so that all part surfaces are exposed to the spray jets, as well as to convey the parts through each process.

The washer is completely automatic: the operator loads the parts into a chute at the entrance of the drum, and the cleaned parts are automatically discharged at the opposite end.