TYPHOON® MB-H

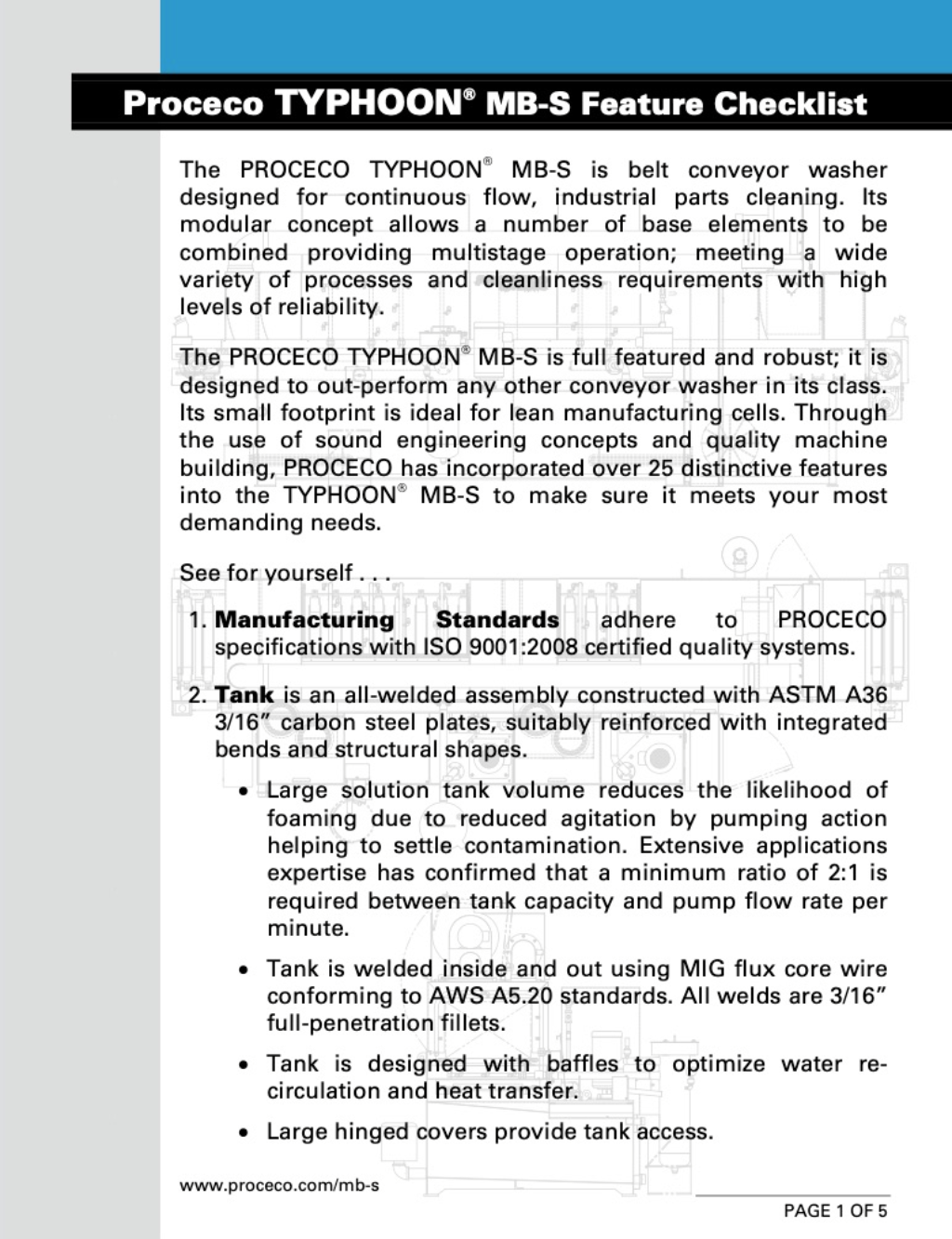

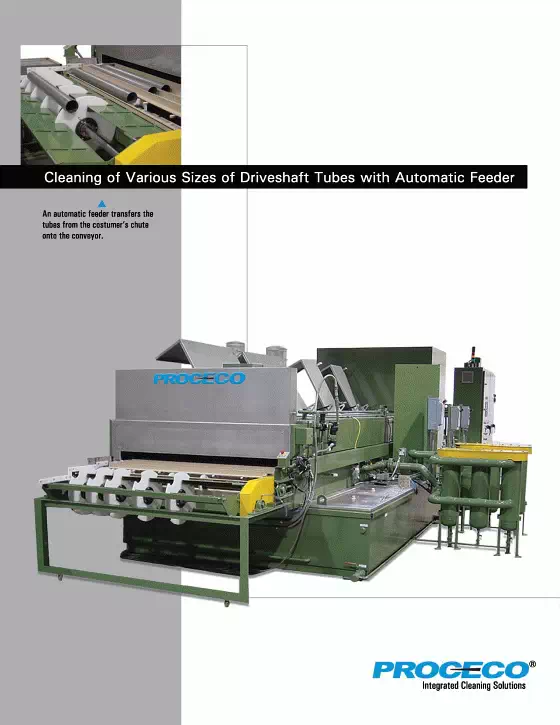

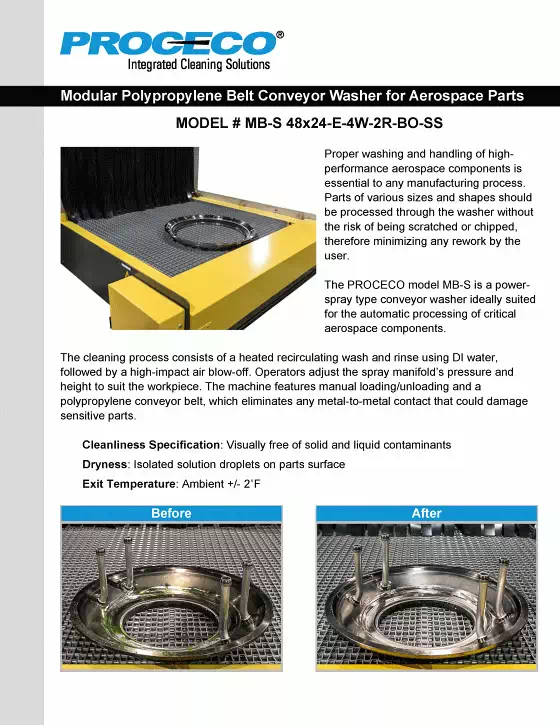

The PROCECO TYPHOON® MB-H is a heavy-duty pass-through conveyor parts washer designed for automatic processing and cleaning of heavily contaminated and/or heavyweight components. Available in capacities of up to 300 pounds per square foot (1465 kg/m2), the TYPHOON® MB-H heavy-duty pass-through parts washer is also available in an optional multi-stage configuration to accommodate required processes such as recirculated wash, recirculated rinse, freshwater rinse, and drying blow-off.

.webp?width=460&height=460&name=Heavy-duty-belt-conveyor-parts-washer-typhoon-mbh2%20(1).webp)

.webp?width=460&height=460&name=Heavy-duty-belt-conveyor-parts-washer-typhoon-mbh3%20(1).webp)

.webp?width=280&height=84&name=ELECTRO%20MOTIVE%20(EMD).webp)