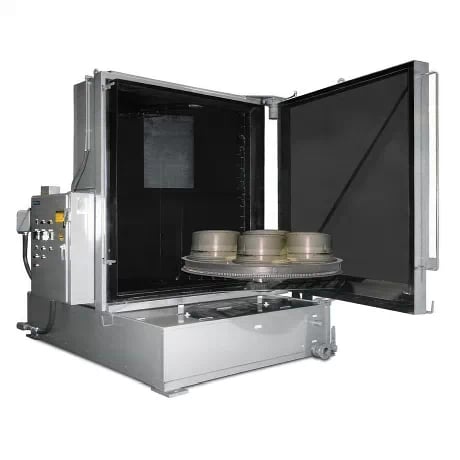

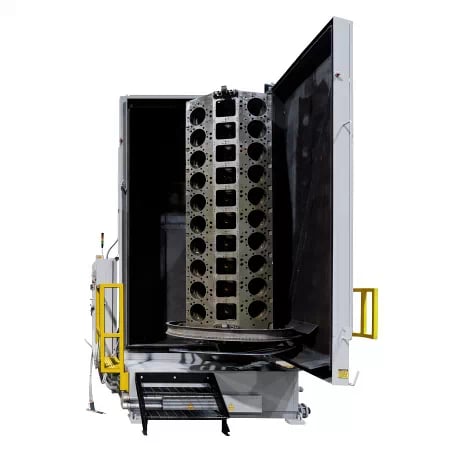

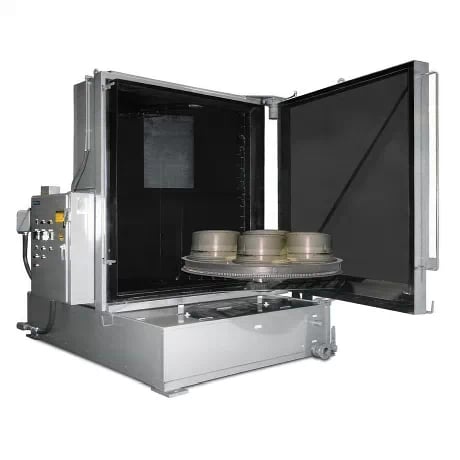

Heavy-Duty Cabinet Parts Washers

TYPHOON®-HD

Key benefits

- Fully automatic and environmentally friendly power spray cleaning process

- PROCECO's exclusive maintenance-free, seal-less process pumps

- Heavy-duty 3/16" welded-steel construction - thermally insulated as standard

- Larger solution tanks for less frequent tank maintenance

- True recirculation: each stage includes its tank and process pump

- More standard features and safety enhancements

Overview

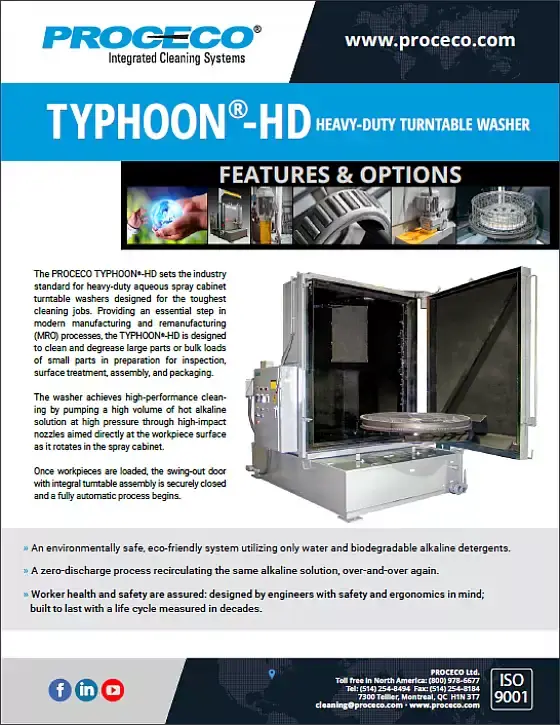

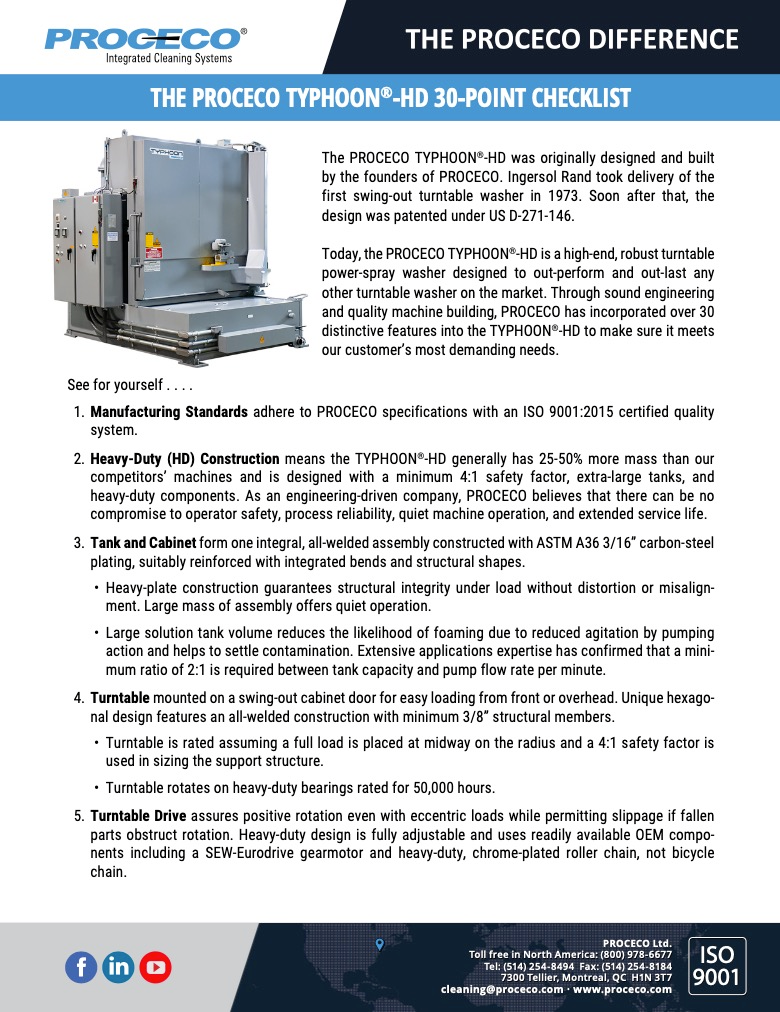

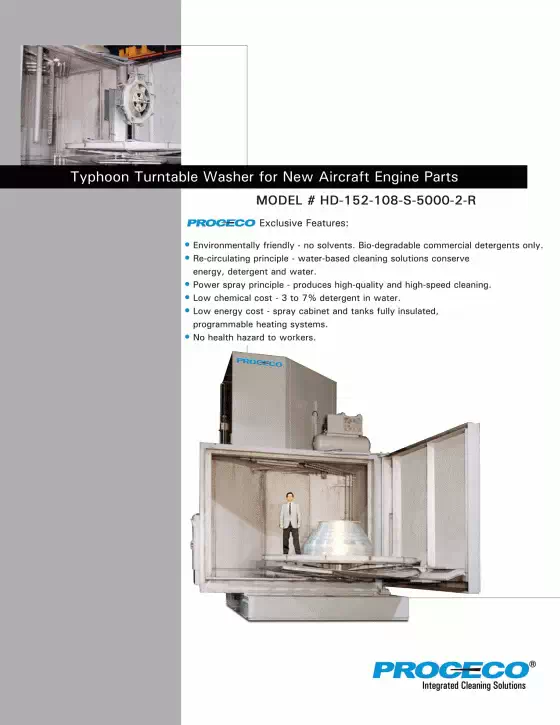

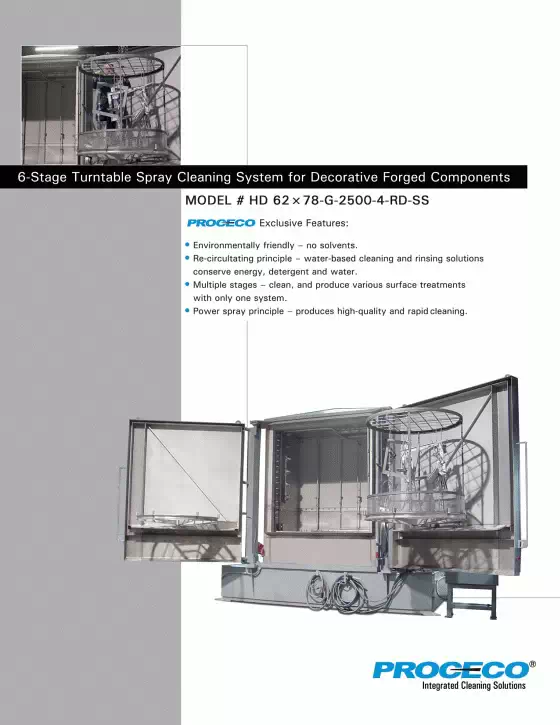

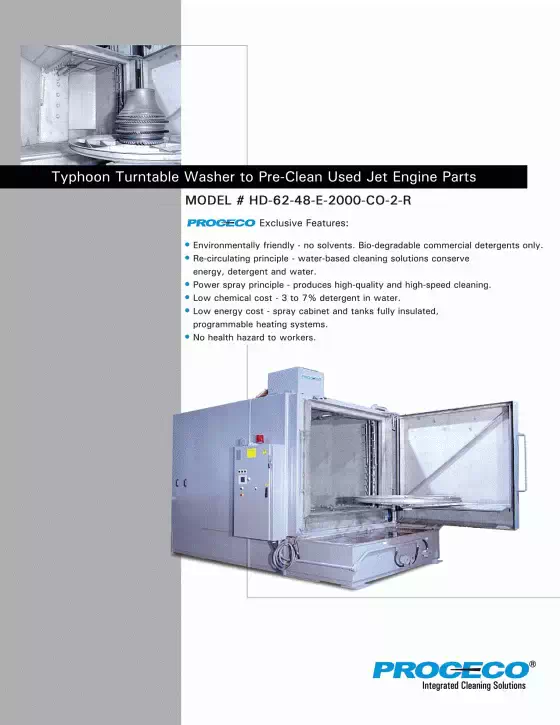

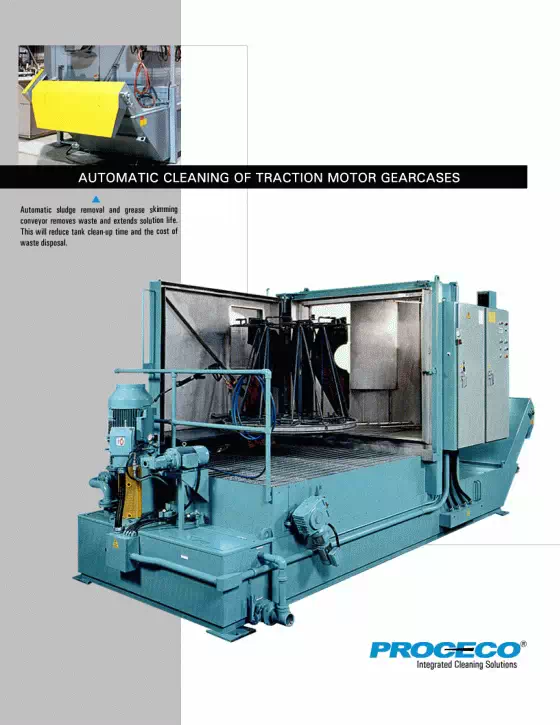

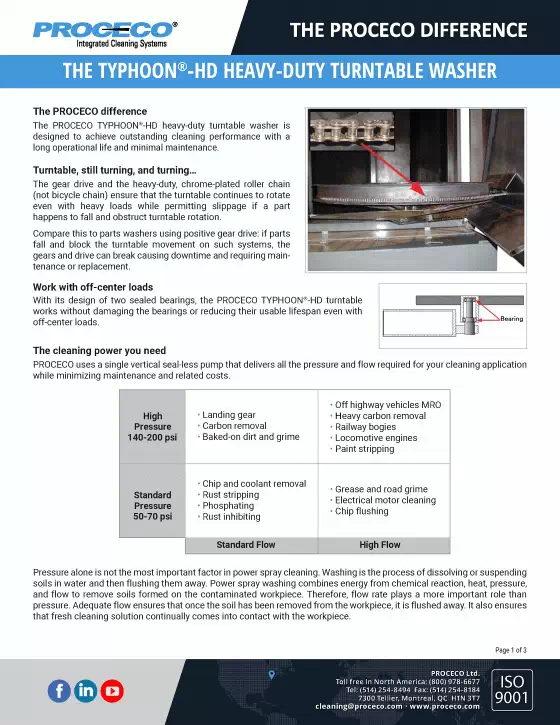

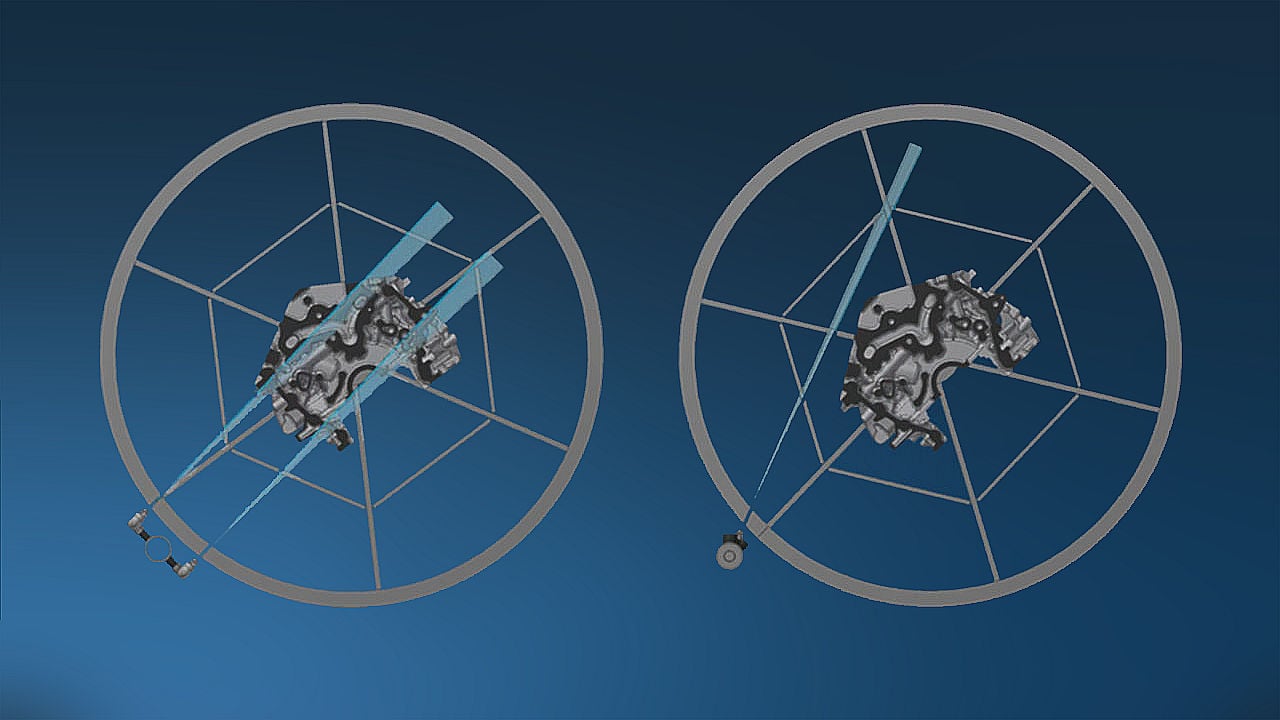

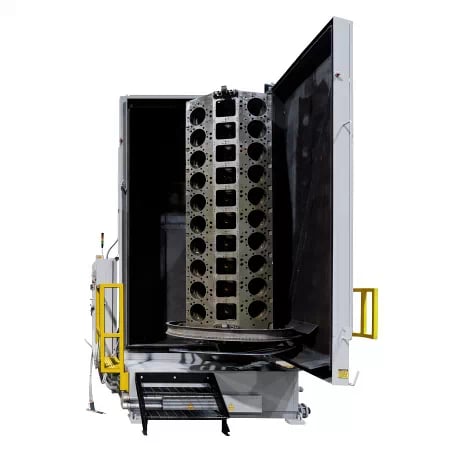

PROCECO TYPHOON®-HD heavy-duty turntable parts washers are designed to clean large parts placed directly on a swing-out turntable or batches of small parts loaded in baskets. Our heavy-duty industrial parts washers combine pressure, heat, and an aqueous cleaning solution to clean and degrease parts to your specification within minutes – ideal for cleaning in manufacturing, maintenance, and remanufacturing applications. In addition to parts cleaning, the TYPHOON®-HD heavy-duty parts washer can also be engineered for sprayed surface-treat processes such as phosphating and passivation.

TYPHOON®-HD's industrial parts washer design features a large-volume solution tank, which reduces the likelihood of foaming by reducing agitation through pumping action, helps to settle contamination, and also reduces tank clean-out frequency. Many other design features, such as low-maintenance pumps, digital temperature controllers, and cycle timers are standard on all PROCECO heavy-duty turntable parts washers. These heavy-duty cabinet parts washers can also be easily customized by choosing from over 40 available pre-engineered options.

- Specification sheets

- Download resources

- Videos

TESTIMONIALS

“I would like to thank you and your staff for the support on the 2nd Washer we've bought from Proceco. It is always great to deal with world class companies in our business ventures...”

Steve Jones

“PROCECO also followed through with timely submittals, met delivery schedules, and provided field service for testing and training to ensure the operations and maintenance groups were comfortable with their new equipment”

Daniel Schiraldi

“...I want to highlight the excellent service and performance that the TYPHOON Bearing Washer has provided us during the approximately 16 years of operation in our facilities. I must say that both its performance and the results achieved have been and continue to be very satisfactory.”

“On behalf of Sun Chemical, I would like to express our thanks to PROCECO for seeing the value of design changes, incorporating those changes on our unit in Cincinnati and hopefully on aII future units.”

George Oliver

“We've noticed that the machine is operating exceptionally well.”

Balaiyasa Yogyakarta

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.