Heavy-Duty Reciprocating Manifolds Parts Washer

TYPHOON®-RCP

Key benefits

- Environmentally friendly power spray cleaning process—no solvents

- Designed to clean large, heavy workpieces while minimizing floor space

- Workpieces can be loaded by forklift or overhead crane

- Fully automatic multi-stage cleaning, which eliminates almost all labor input

- Effectively removes tenacious soils such as grease, carbon, and even paint

- Complete coverage of all surfaces

Overview

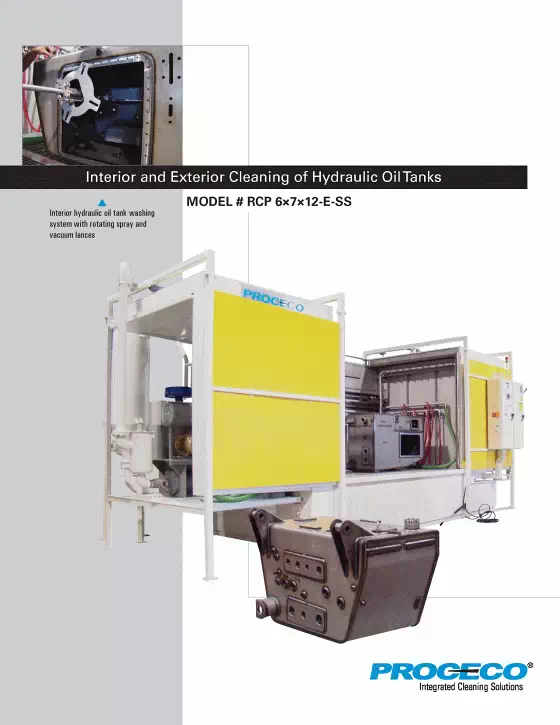

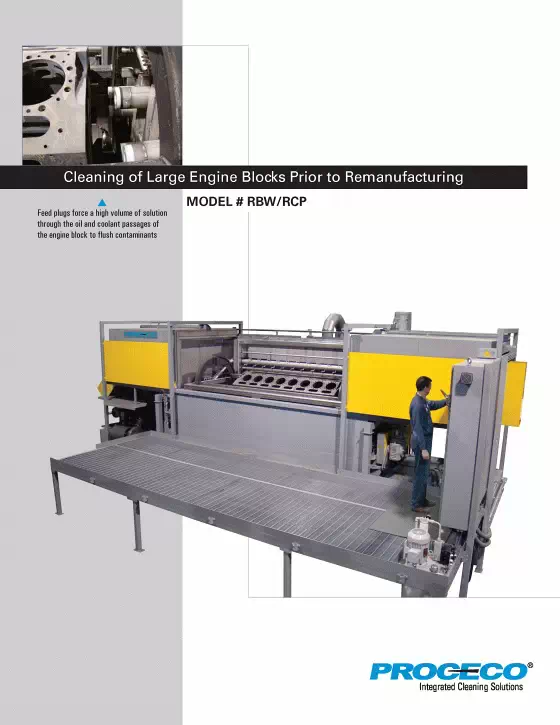

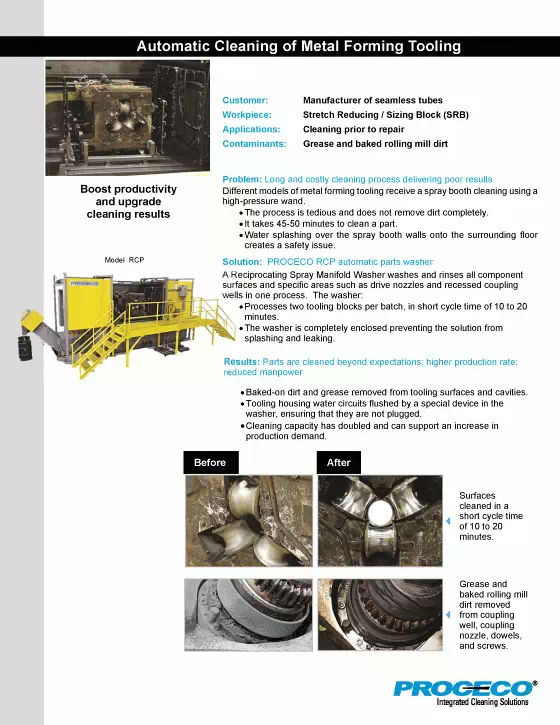

The PROCECO TYPHOON®-RCP is a batch-type power-spray heavy-duty parts washer designed to clean large, heavy workpieces while taking up minimal floor space. The TYPHOON®-RCP heavy-duty parts washer's typical applications include cleaning of die, heavy machinery hydraulic components, and diesel engine blocks. The double sliding doors provide wide access for easy top loading with a hoist or front loading with a forklift.

PROCECO cleaning technology uses environmentally friendly, water-based cleaning solutions instead of harmful solvents. The cleaning process of this heavy-duty parts washer consists of a wash stage using a continuously recirculated, hot-water cleaning solution. A spray manifold surrounding all four sides of the stationary workpiece power sprays the cleaning solution and travels back and forth across the entire length of the part, ensuring complete coverage of all surfaces. Within a short cycle time, the heavy-duty Reciprocating Nozzle Frame Washer effectively removes oil, grease, debris, and dust from part surfaces.

The PROCECO TYPHOON®-RCP is an ideal heavy-duty parts washer for rebuild and remanufacturing applications. This industrial parts washer can also incorporate a selection of options for removing oil and sludge from the solution, which substantially extends solution life and reduces the need for manual tank clean-out.

In addition to processing large workpieces in the TYPHOON®-RCP, machine operators can place smaller parts such as disassembled fittings, etc. in baskets and load them into the RCP for cleaning.

- Specification sheets

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

-

TESTIMONIALS

“... Your office staff and technicians were easy to work with and extremely professional. We appreciate your ability to deal with the changes involved in this project...”

John Heter

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.