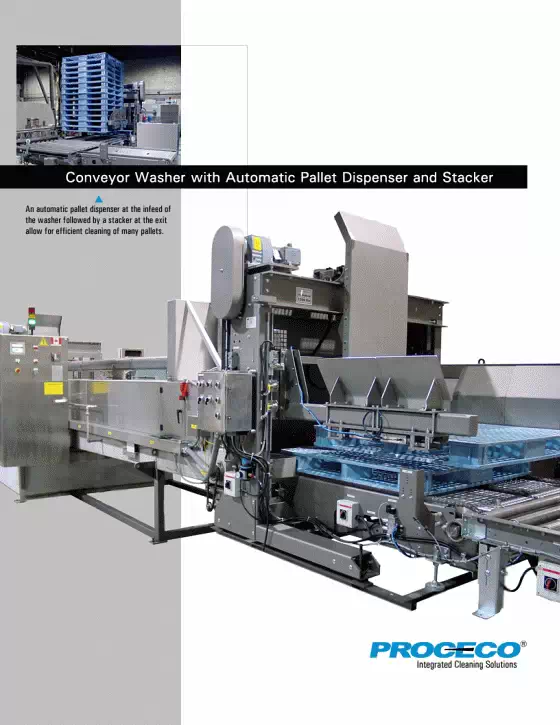

Parts Washer for Plastic Dunnage Pallets & Trays

TYPHOON® MB-D

Key benefits

- Efficient and completely automated process

- Remove machining oils, coolants, metal chips, shop dust, and other soils

- Full solution recirculation to conserve water, detergent, and heat

- Large access doors for easy maintenance

- Stainless-steel construction for long service life with mild cleaners

- Integrated high-velocity blow-off to remove excess water

Overview

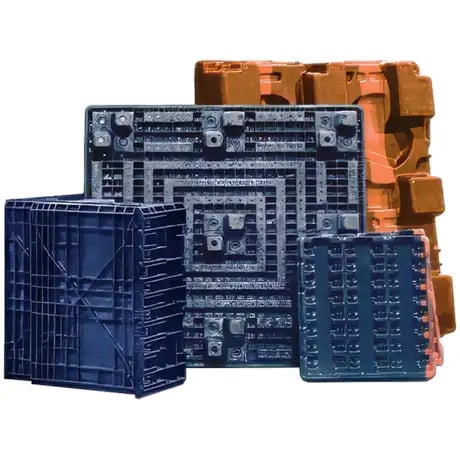

The TYPHOON® MB-D washer automatically cleans and dries a variety of types and sizes of reusable plastic dunnage, trays and pallets in a continuous process. A hot aqueous cleaning solution is sprayed on all dunnage surfaces to remove machining oil, coolants, metal chips, transport dust, and dirt. The solution is recirculated to conserve water, detergent, and heat.

Clean dunnage exits the washer after having passed through the high-impact, air blow-off drying stage. An optional automatic return conveyor can be added to return the dunnage to the loading side, enabling a single operator to load and unload the system. Other options are available for tailoring the MB-D dunnage washer to meet your cleaning requirements.

- Specification sheets

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

TESTIMONIALS

"... Our ability to now service our customer(s) with a stream line Dunnage/Packaging Cleaning Process, will allow our company to grow and become more versatile now, and heading into the future. We have PROCECO to thank, for that opportunity and ability...”

Jason Baier

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.