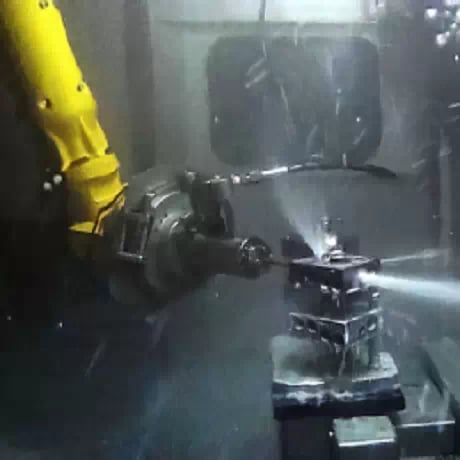

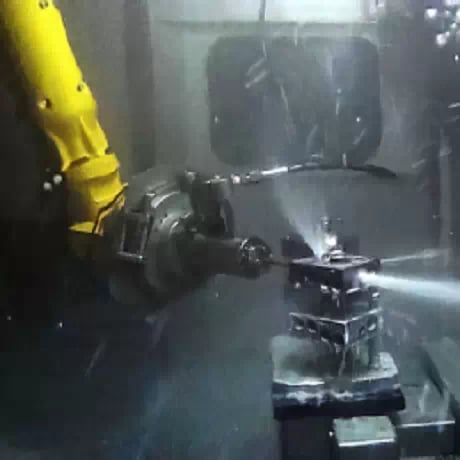

Robotic Water-Based Deburring and Flushing System

RDB-700

Key benefits

- Precision deburring & flushing

- Features a foundry-grade multi-axis robot

- Available with high-speed precision rotary indexing table

- Ideal for workpieces with cavities and intersecting holes

- Replaceable high-pressure tooling offers flexibility and repeatability

- Full solution recirculation to conserve water, detergent, and heat

PROCECO RDB-700 is a six-axis robotic cleaning and deburring system designed to remove burrs, chips, and non-parent material from medium-sized, complex machined components. Using high-pressure rotary water jets, the articulating robot is programmed to position a lance nozzle to deburr all the machined holes, intersections, and difficult-to-access cavities of a steel or aluminum workpiece mounted on a fixture. The lance nozzle precisely sprays a pressurized, water-based solution to clean, flush, and deburr in a single operation. After cleaning, air is directed through the lance nozzle and the robot again passes through all machined areas, blowing excess solution away from the part.

The RDB-700 is a flexible system that combines reliability, precision, and quality — ideally suited to a machine shop environment.

- t

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.