Precision Parts Washers for Industrial Manufacturing

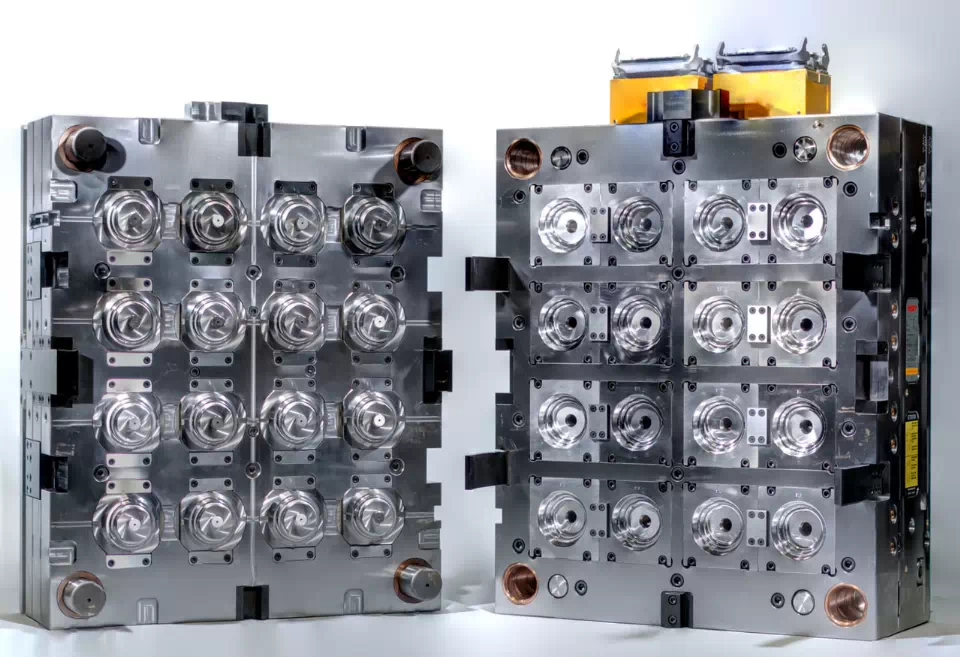

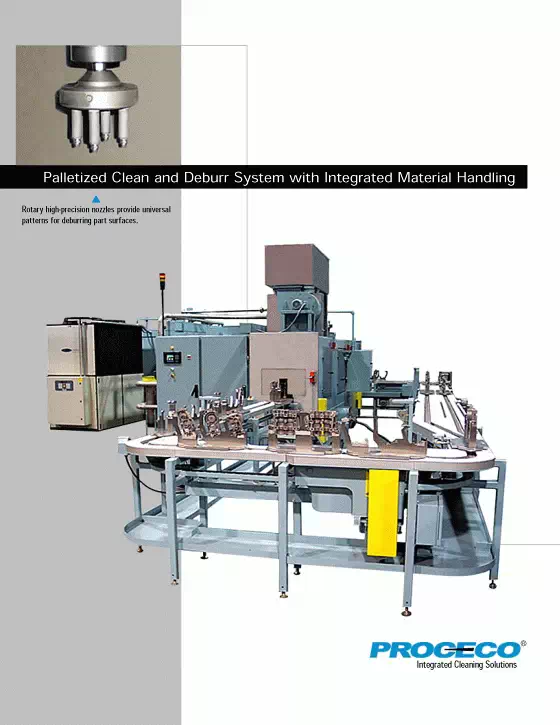

We build precision parts washers to meet the demanding needs of industrial manufacturing. Designed for smaller, intricate applications, these systems excel in removing chips, oils, cutting fluids, and other contaminants from decorative forged components, machined parts, and high-precision assemblies. PROCECO’s cutting-edge technology drives optimal manufacturing performance, ensures superior quality, and minimizes production downtime.

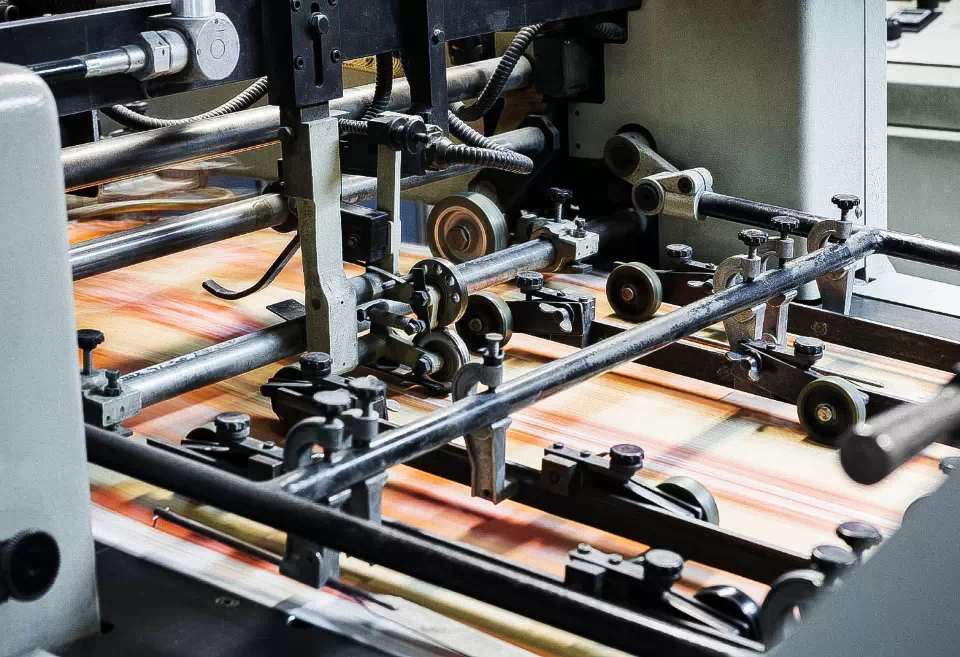

Designed for versatility, our industrial cleaning systems handle a wide range of manufacturing applications, including chip removal, surface preparation for decorative parts, and cleaning complex machined components. They deliver reliable and precise results, helping manufacturers meet exacting quality standards and ensure defect-free production.

By improving production workflows, our systems enhance operational efficiency, reduce machining costs, and ensure consistent part cleanliness. Trusted by manufacturers worldwide, our advanced cleaning solutions keep your processes running smoothly and ensure that your products meet the highest standards of quality.

Properly Cleaned Parts Prior to Subsequent Operations or For Final Assembly

Optimize your manufacturing process with our PROCECO parts washers—engineered for flawless results in every application!

Industrial Manufacturing Components

Effective cleaning is critical in industrial manufacturing to maintain quality and precision. Chips, oils, and other contaminants can lead to defects, increased reject rates, and costly rework. PROCECO parts washers deliver exceptional cleanliness, consistent finishes, and enhanced product reliability for decorative forged parts, machined components, and intricate assemblies.

Large Parts Washers for Industrial Manufacturing Components

Since 1975, PROCECO has delivered advanced cleaning systems to metal parts and component manufacturers, ensuring superior cleaning for new applications like chip removal, decorative finishes, and precision machining. With over 1000 systems installed globally, we exceed industry expectations by enhancing productivity, improving part quality, and meeting evolving manufacturing demands.

Industrial Manufacturing Applications

- Cleaning of Industrial Manufacturing Components

- Surface Treatment for Metal Parts

-

Industrial Manufacturing Metal Parts Cleaning

PROCECO’s industrial parts washers are designed for a wide range of parts cleaning operations, from precision metalworking processes to remanufacturing operations. Our Industrial parts washers use recirculating hot water and environmentally safe detergents to provide the cleaning action required for your specific application.

We will help you select the most effective cleaning equipment configurations and chemistries to meet your requirements, from simply removing metal working fluids, metal chips, and abrasives — to more challenging applications such as removing grease, grime, baked-on carbon deposits, and even paint.

-

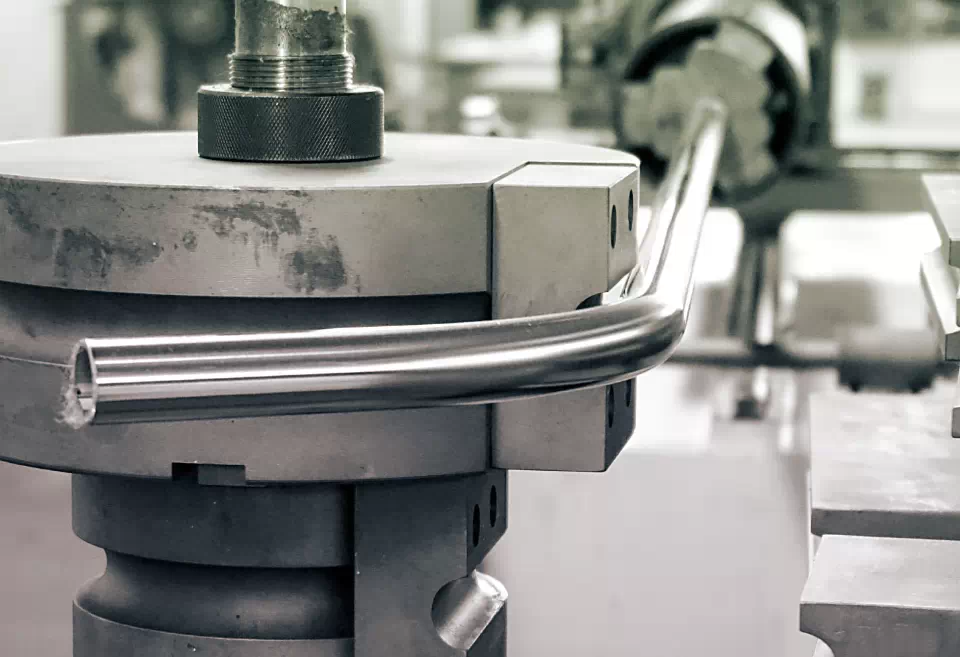

Surface Treatment for Metal Parts

In addition to cleaning and rinsing, PROCECO's surface treatment equipment allows the application of additional processes to a part's surface to improve its aesthetic qualities or boost its resistance to rust and wear.

TESTIMONIALS

“... I want to encourage you to keep up the good work. It's quality like this that will keep me returning to your company for future washers..”

Gene Mitchell

“...the quality and service we have received has allowed us to stay in step with Caterpillar's ever increasing cleanliness requirements...”

Steven Gugan

“I would like to thank you and your staff for the support on the 2nd Washer we've bought from PROCECO. It is always great to deal with world class companies in our business ventures...”

Steve Jones

“I appreciated your hard work, willingness to get your hands dirty, so that we had a successful and on time start up of the equipment...”

.webp?width=280&height=84&name=ELECTRO%20MOTIVE%20(EMD).webp)

Eric den Bak

“... I want to highlight the excellent service and performance that the TYPHOON Bearing Washer has provided us during the approximately 16 years of operation in our facilities. I must say that both its performance and the results achieved have been and continue to be very satisfactory....”

Eduardo Perez

“I wanted to take the time to express my personal appreciation of the work performed by PROCECO's installation and commissioning crew. Our top management commented on how smoothly the crankshaft washer came in and how quick it was operational.”

Chris Taylor

“The experience of working with PROCECO's professional staff was both pleasurable, and educational. Your achievement in meeting our difficult deadlines as well as our specifications did not go unnoticed...”

Steve Waananen

“We have received many compliments from customers contractor and service personnel on the design and construction of the l-2-E pray Washer. It started up monthly and is performing very well providing consistent performance and quality.”

Ken Barthelemy

The installation was a success [...] Proceco Provided two machines on-site in a very timely, well-organized, and cost-efficient manner.

Thank you for all of the hard work. I look forward to working with Proceco again in the future on any other cleaning endeavors.

Joshua D. Gore

“On behalf of Sun Chemical, I would like to express our thanks to PROCECO for seeing the value of design changes, incorporating those changes on our unit in Cincinnati and hopefully on a II future units.”

George Oliver

“... this is the most user-friendly design of any waste water treatment equipment that I have come across—we are able to operate it with nothing more than the recommended preventive maintenance labor, the rest has been fully automatic.”

Rob Curtis

“... PROCECO excelled through purchasing, planning, delivery, quality and installation to the highest expectation...”

Lawrence Zhu

“Your office staff and technicians were easy to work with and extremely professional. We appreciate your ability to deal with the changes involved in this project...”

John Heter

"... Our ability to now service our customer(s) with a stream line Dunnage/Packaging Cleaning Process, will allow our company to grow and become more versatile now, and heading into the future. We have PROCECO to thank, for that opportunity and ability...”

Jason Baier

“... we immediately ran our product through it. The results were outstanding. It cleaned the product so well that we will actually use a shorter cycle time than what we had anticipated...”

Curtis Malone

Our Trusted Partners in The Industrial Manufacturing Industry

Industrial Manufacturing Resources

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.