Parts Washers and Cleaning Systems for the Automotive Industry

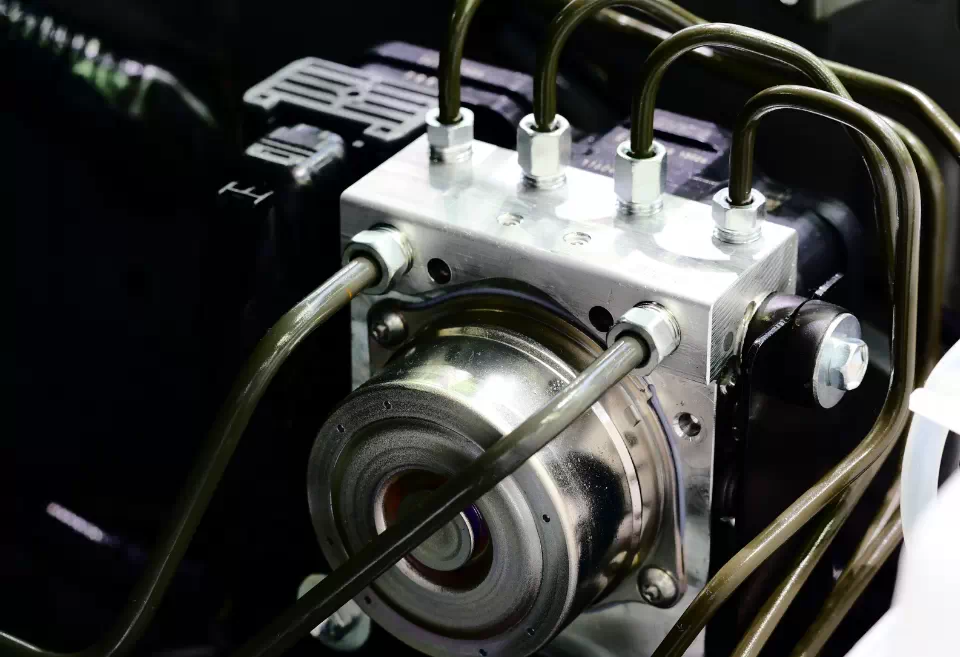

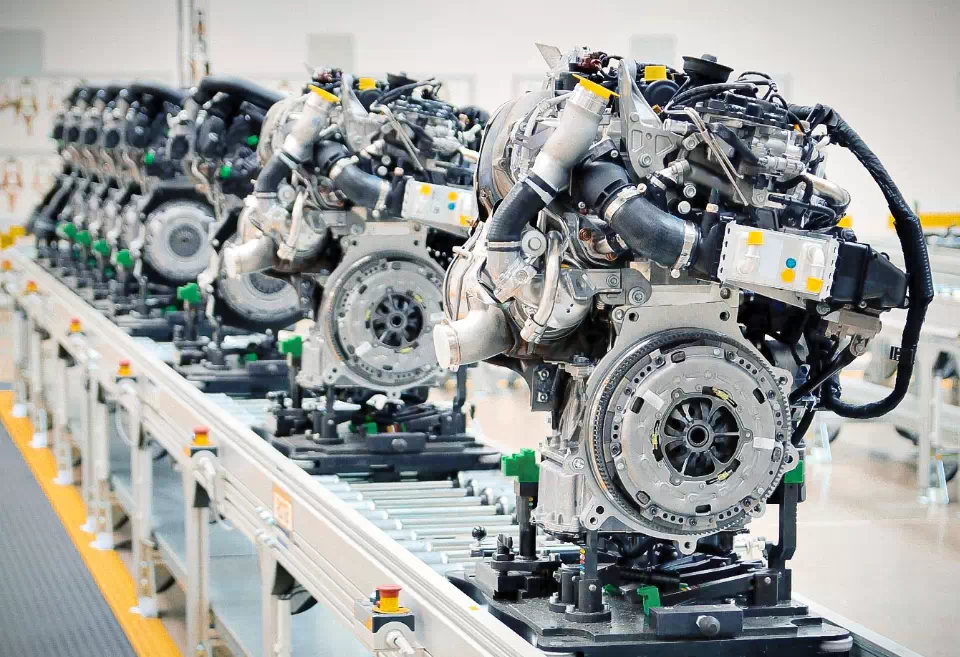

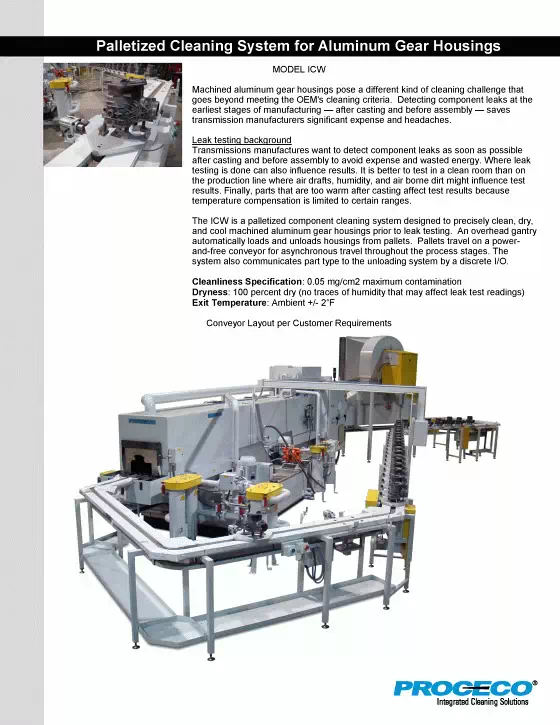

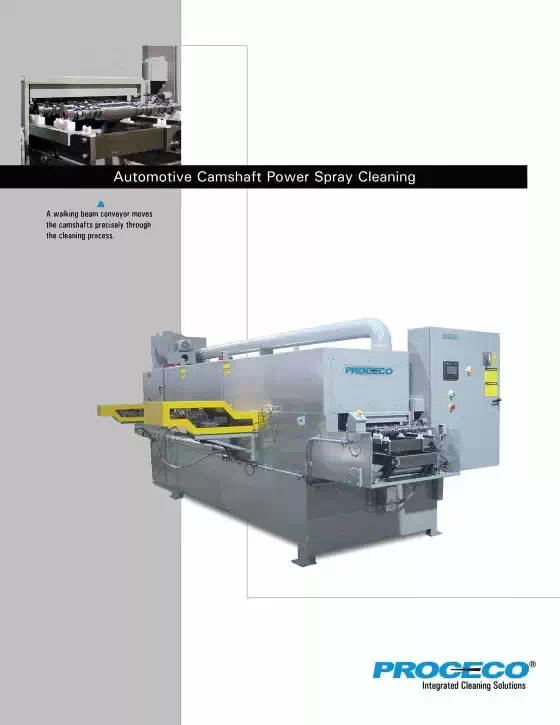

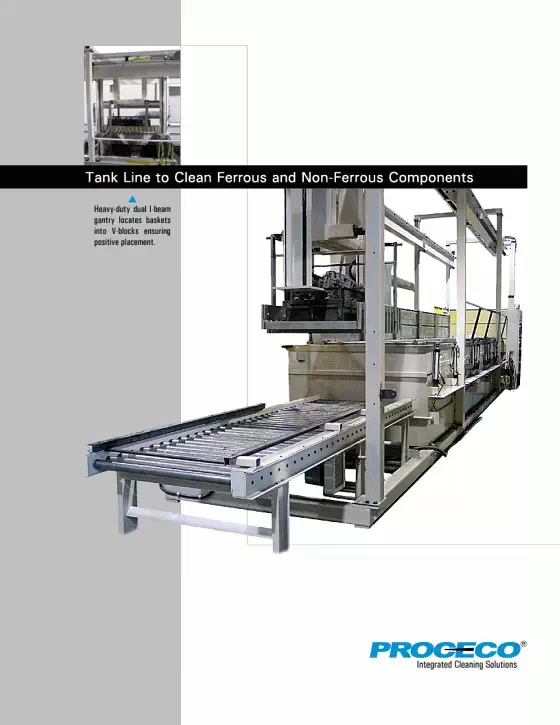

PROCECO's state-of-the-art aqueous parts washers and cleaning systems remove machining oil, chips, and contaminants from parts such as engine blocks, cylinder heads, oil pump components, and camshafts. Whether in a lean manufacturing environment or large-scale production, our custom-engineered cleaning systems will meet your cleanliness specifications and production rates.

Since 1975, Tier 1 & 2 automotive component manufacturers and OEMs around the world have relied on PROCECO parts washers and cleaning systems to increase their productivity, profitability and product quality. In the global automotive industry, PROCECO has engineered and supplied over 2,000 parts washers and cleaning systems, each of which far exceeds conventional design standards.

Achieve High-Production Rate Requirements

PROCECO Parts Washers are tailored specifically to serve the time-sensitive and rigorous automotive industry.

Automotive Components

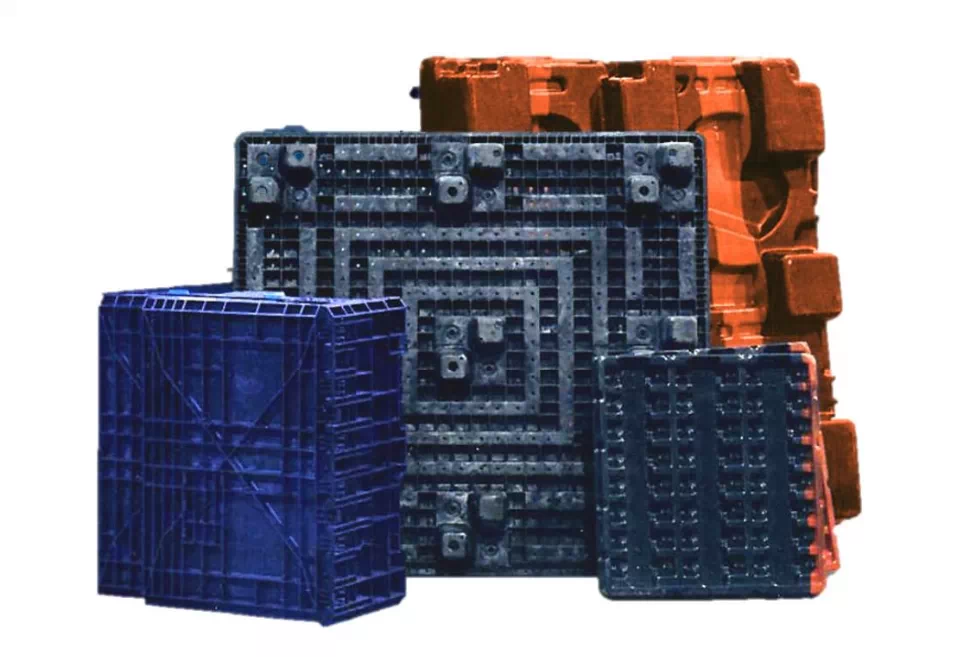

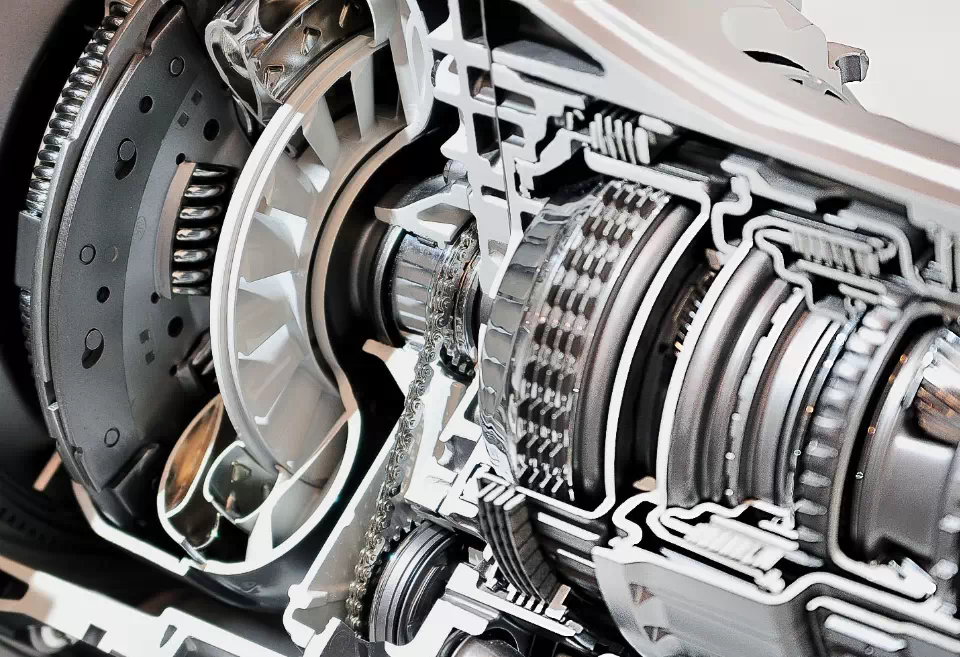

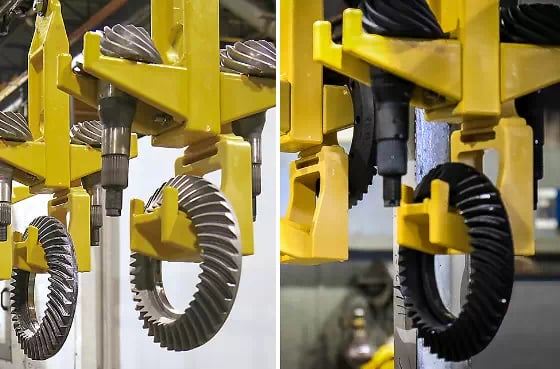

PROCECO offers a complete range of equipment specifically designed for automotive components such as transmissions, powertrains, drivetrains, engines, brakes, steering, and dunnage.

Our expertise allows us to develop flexible cleaning systems that ensure all components are properly cleaned to meet stringent automotive cleanliness requirements at the lowest possible cost to you.

Automotive PARTS WASHERS

Automotive Applications

- Parts Cleaning for Automotive Applications

- Fluorescent Penetrant Inspection for Automotive Applications

- Surface Treatment for Automotive Applications

-

Parts Cleaning for Automotive Applications

Since 1975, Tier 1/Tier 2 automotive component manufacturers and OEMs around the world have relied on PROCECO cleaning systems to increase their productivity, profitability, and product quality. In the global automotive industry, PROCECO has engineered and supplied over 2,000 parts washers and cleaning systems, each of which far exceeds conventional design standards. -

Fluorescent Penetrant Inspection for Automotive Applications

In the automotive industry, fluorescent penetrant inspection is used to detect any surface discontinuities such as cracks, quenching, and grinding, as well as fractures, porosity, incomplete fusion, and flaws in joints. PROCECO has designed and custom-built multiple-stage FPI Systems for automatic parts processing. -

Surface Treatment for Automotive Applications

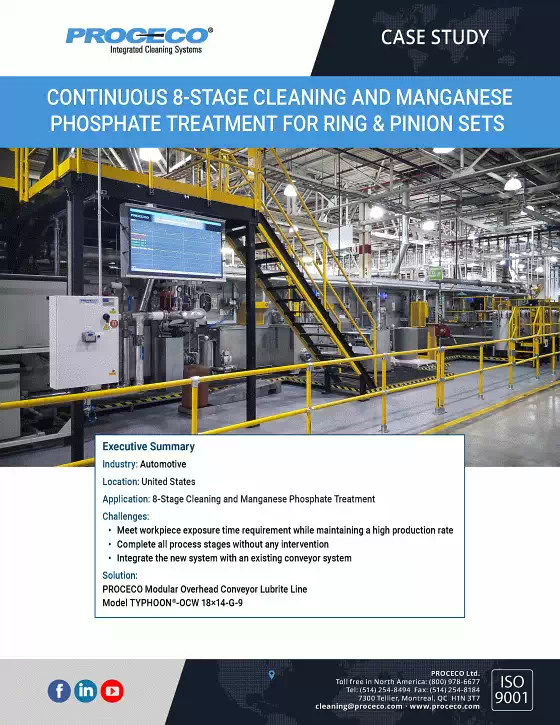

For both functional and aesthetic reasons, the automotive industry uses surface treatments in the production of metal parts. The requirements for automotive systems include reduced weight and friction, longer component lifespan, and enhanced corrosion resistance.

PROCECO has had the opportunity to partner with leading companies in the sector to provide or replace their cleaning and surface treatment systems.

TESTIMONIALS

“... I am confident we made the right choice in

selecting PROCECO for this project and I expect that we will be working together again in the future as we have additional washing needs...”

Anil Patel

“... where did you get your part washer? The name PROCECO was the go-to company for part washing. I did research three vendors for our requirements. PROCECO clearly was the leader in the procurement process...”

Todd Martin

“...the washer has been working perfectly and consistently delivers clean parts, increasing the quality of our laser welding. We were so pleased with the results that we decided to award them a second project.”

John Cardea

“...PROCECO has demonstrated the supplier “partner” Ford is looking for in long term plans of the company...”

Robert L. Lorenz

“...PROCECO also reacted with creative problem solving when faced with a delinquent delivery response from a Metaldyne dictated pump supplier...”

Gume Reyna

“...the whole team at PROCECO, and wish to extend our sincere thanks for your commitment to meeting our expectations. I am confident we made the right choice in selecting PROCECO for this project...”

Nathaniel E. Wayman

“...They often took the initiative to get things started and picked up the slack when things were going slowly. I was glad to work with them, because we were able to complete the buy-off on time.”

Tibor Tamas

“...The comments from people on the floor to upper management have been nothing but very positive, especially with the fit and finish of stainless steel work. These machines are showcases...”

Kevin Tripi

“... I would like to also say that start-up went better than any supplier that Getrag has been associated with. There are always "Bugs", but the installation went great. Problems were very minor and were dealt with on the spot..”

John Cardea

“... Just a short note to thank you for the excellent service PROCECO has provided to BorgWarner. We have now purchased eight washers from PROCECO and every aspect of the process went smoothly...”

Grover DeHart

“...the washer has cycled through 40 to 50 cycles

at this time. The performance and versatility has been fantastic. Once we started using the washer for our production pieces, we found other items in our department needing to be washed...”

Joseph D.Loukota

Our TRUSTED PARTNERS IN THE Automotive INDUSTRY

Automotive RESOURCES

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.