Return-to-Operator Rotary Parts Washer

TYPHOON®-RW

Key benefits

- For continuous cleaning of manufactured components

- Single-point loading/unloading is ideal for lean manufacturing cells

- Compact / Ergonomic design with all services at the rear

- Precision-aimed nozzles and blow-off for maximum cleanliness and dryness

- Ideal for automatic loading

- PLC controlled

Overview

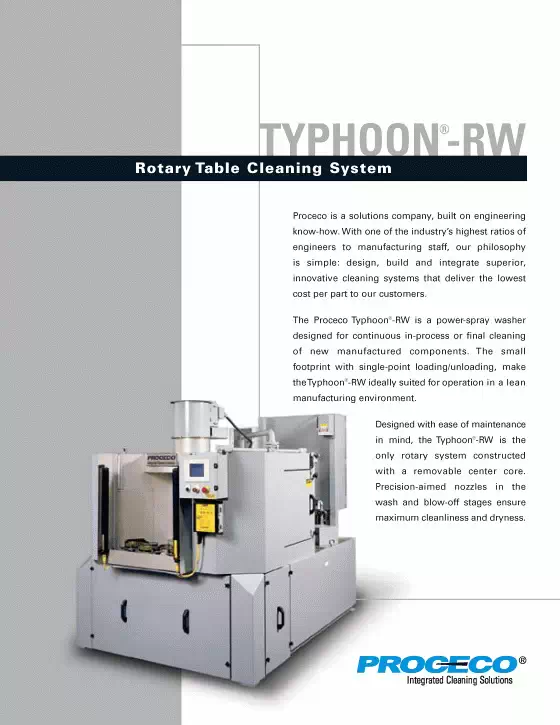

PROCECO TYPHOON®-RW is an indexing parts washer designed for final or in-process cleaning and drying of new manufactured components. The RW is a compact spray cleaning system that can accommodate high production requirements using a single load/unload point, making it ideal for cellular applications. The system can be customized to meet your requirements by adding optional features and additional processes such as a recirculated rinse and high-pressure water-jet deburring.

The narrow machine width with single point load and unload station is ideally suited for lean manufacturing cell operation. All service connections and major service points are located at the rear of the washer so it may be installed with minimal clearance with adjacent equipment.

The standard process is a recirculating spray wash cycle using a heated aqueous based detergent, followed by an air blow-off. A High Impact blower supplies high-pressure air to provide the impact required to displace water from the workpiece. The air is not recirculated in this system, so only clean dry air (supplied by the blower from the plant atmosphere) is in contact with the workpiece.

All key cleaning and drying components are designed specifically for the workpiece to be processed and are easily exchanged on site should production requirements change in the future.

- Specification sheets

- Download resources

- Videos

-

Work HeightWork Height42”48”56”60”72”84”108”

CONTACT A SOLUTION EXPERT

PROCECO develops aqueous cleaning systems that go beyond cleaning, by seamlessly integrating a wide range of processes and features that dramatically improve your productivity and profitability.